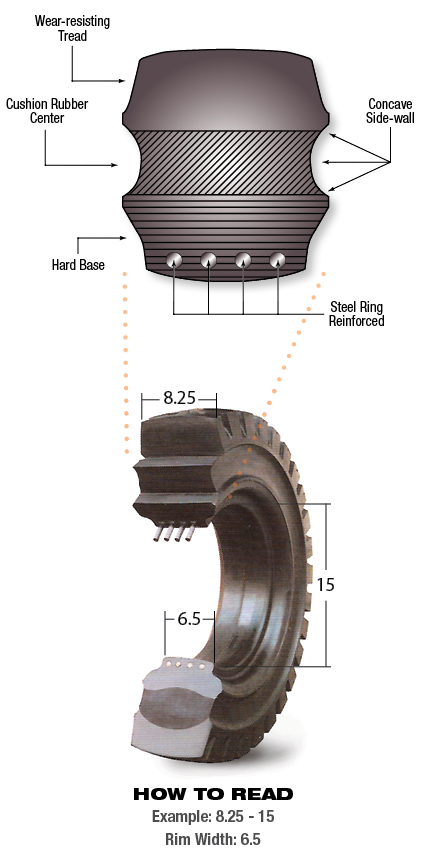

Pneumatic Shaped Solid Tires

Pneumatic shaped solids are compatible with standard pneumatic rims typically used in most material handling applications.

ADVANTAGES:

- Longer wear and extended service life

- High shock absorption properties, smooth ride

- Low energy consumption

- Good stability and braking in high load applications

THREE LAYER CONSTRUCTION:

- High strength steel reinforced base rubber – eliminating wheel spin, and fining in high torque applications

- Energy efficient cushion mid-layer – provides good shock absorption reducing shock transmit ion to material handling equipment

- Wear resistant tread – providing extended service life, stability and improved braking properties

SERIES:

- Forte series 8″ – 15″

- Forte and NUMA series 16″ – 25″

- The Forte series is energy efficient compound, cool running in severe service applications. Extended service life through high degree of chunk and chip resistance. Suitable for large engineered vehicles, sea port and container applications.

- High performance Non-Marking Tires are available for applications where “Keeping It Clean” is a priority. This compound will not mark floors in short turn radius applications. Suitable for use in warehouses, pharmaceutical plants, food and beverage facilities.

Resilient Tires Tackles Your Tire Needs Head On

A new line of tires designed to meet a wide variety of material handling applications:

- “Forte” Series – Best for the toughest of applications

- “NUMA” Series – meets most material handling needs and competitively priced

- “Talon AER” Series – designed with aperture system for improved traction and ride

CLICK HERE to download a pdf file of the chart.

Forte Solid Resilient |

|||||||||

| Part Number | Tire Size | Profile | Rim width (in.) | Tire O.D. | Max width | Tread width | Load Capacity | Weight (lbs.) | |

| 6 mph | 10 mph | ||||||||

| NU-4008-300 | 400 x 8 | RIB | 3 | 16 | 5 | 5 | 2,320 | 1,685 | 25.5 |

| NU-4008-300-NM | 400 x 8 | LUG | 3 | 16 | 5 | 5 | 2,320 | 1,685 | 26.0 |

| NU-4008-375 | 400 x 8 | RIB | 3.75 | 16 | 5 | 5 | 2,900 | 2,105 | 27.8 |

| NU-4008-375-NM | 400 x 8 | LUG | 3.75 | 16 | 5 | 5 | 2,900 | 2,105 | 27 |

| NU-5008-300 | 500 x 8 | RIB | 3 | 17.9 | 6 | 5 | 2,670 | 1,935 | 39 |

| NU-5008-300-NM | 500 x 8 | LUG | 3 | 17.9 | 6 | 5 | 2,670 | 1,935 | 39 |

| NU-5008-375 | 500 x 8 | RIB | 3.75 | 17.9 | 6 | 5 | 3,340 | 2,420 | 39.8 |

| NU-5008-375-NM | 500 x 8 | LUG | 3.75 | 17.9 | 6 | 5 | 3,340 | 2,420 | 38.8 |

| NU-154.58-300 | 15 x 4.5-8 | LUG | 3 | 15 | 5 | 4 | 2,000 | 1,450 | 22.4 |

| NU-1668-433 | 16 x 6-8 | RIB | 4.33 | 16 | 6 | 6 | 3,170 | 2,300 | 35 |

| NU-1878-433 | 18 x 7-8 | LUG | 4.33 | 18 | 7 | 6 | 3,750 | 2,700 | 45.5 |

| NU-2189-600 | 21 x 8-9 | LUG | 6 | 20.8 | 8 | 7 | 6,190 | 4,480 | 78.3 |

| NU-6009-400 | 600 x 9 | RIB | 4 | 21.4 | 6 | 5 | 4,230 | 3,065 | 64.3 |

| NU-6009-400-NM | 600 x 9 | LUG | 4 | 21.4 | 6 | 5 | 4,230 | 3,065 | 62 |

| NU-2005010-650 | 200/50-10 | LUG | 6.5 | 18 | 8 | 7 | 5,200 | 3,770 | 55.5 |

| NU-23910-650 | 23 x 9-10 | LUG | 6.5 | 22.7 | 8.5 | 7.8 | 7,520 | 5,450 | 101.5 |

| NU-65010-500 | 650 x 10 | LUG | 5 | 23.4 | 6.9 | 5.6 | 5,810 | 4,210 | 84.3 |

| NU-231012-800 | 23 x 10-12 | LUG | 8 | 22.8 | 9 | 9 | 8,820 | 6,385 | 97.5 |

| NU-271012-800 | 27 x 10-12 | LUG | 8 | 26.6 | 9.5 | 9 | 10,681 | 7,735 | 166.9 |

| NU-70012-500 | 700 x 12 | LUG | 5 | 27 | 7.4 | 6 | 6,640 | 4,810 | 113 |

| NU-70015-550 | 700 x 15 | LUG | 5.5 | 28.8 | 8 | 7.2 | 7,900 | 5,725 | 133 |

| NU-70015-600 | 700 x 15 | LUG | 6 | 34.5 | 8.6 | 7.3 | 10,125 | 7,330 | 135 |

| NU-750-15-550 | 750 x 15 | – | – | – | – | – | – | – | – |

| NU-750-15-660 | 750 x 15 | – | – | – | – | – | – | – | – |

| NU-28915-650 | 815 x 15 (28×9-15) | LUG | 6.5 | 27.7 | 8.7 | 7.9 | 8,360 | 6,055 | 136 |

| NU-28915-700 | 815 x 15 (28×9-15) | LUG | 7 | 27.7 | 8.7 | 7.9 | 9,000 | 6,520 | 129.8 |

| NU-82515-550 | 825 x 15 | LUG | 5.5 | 33.5 | 9.1 | 7.8 | 9,200 | 6,665 | 208 |

| NU-82515-650 | 825 x 15 | LUG | 6.5 | 33.5 | 9.1 | 7.8 | 10,870 | 7,875 | 215 |

| NU-25015-700 | 250 x 15 | LUG | 7 | 29.5 | 9.2 | 8.5 | 9,610 | 6,960 | 174 |

| NU-25015-750 | 250 x 15 | LUG | 7.5 | 29.5 | 9.2 | 8.5 | 10,300 | 7,460 | 177 |

| NU-30015-800 | 300 x 15 | LUG | 8 | 32.5 | 11 | 10.8 | 13,190 | 9,550 | 270 |

| NU-2812.515-975 | 28 x 12.5-15 | LUG | 9.75 | 28.0 | 12 | 11.2 | 12,760 | 9,250 | 188.8 |

| NU-3556515-975 | 355/65-15 | LUG | 9.75 | 32.9 | 11.8 | 11.1 | 15,410 | 11,165 | 281 |

| NU-65016-550 | 650 x 16 | LUG | 5.5 | 29.5 | 7 | 6.3 | 7,580 | 5,490 | 118.8 |

| NU-75016-550 | 750 x 16 | LUG | 5.5 | 31.5 | 8.2 | 6.5 | 8,610 | 6,420 | 162 |

| NU-750-16-600 | 750 x 16 | – | – | – | – | – | – | – | – |

| NU-82520-650 | 825 x 20 | LUG | 6.5 | 37.9 | 8.6 | 7.8 | 11,950 | 8,655 | 244 |

| NU-90020-650 | 900 x 20 | LUG | 6.5 | 39.9 | 10.1 | 9.1 | 13,200 | 9,650 | 297.8 |

| NU-100020-75S | 1000 x 20 | SMOOTH | 7.5 | ||||||

| NU-100020-750 | 1000 x 20 | LUG | 7.5 | 41 | 10.7 | 9.7 | 13,820 | 10,010 | 380 |

| NU-100020-800 | 1000 x 20 | LUG | 8 | 41 | 10.7 | 9.7 | 17,010 | 12,320 | 386 |

| NU-10002010 | 1200 x 20 | LUG | 10 | ||||||

| NU-120020-800 | 1200 x 20 | LUG | 8 | 43.0 | 11.5 | 10.5 | 18,600 | 13,475 | 435 |

| NU-120020-850 | 1200 x 20 | LUG | 8.5 | 43.0 | 11.5 | 10.5 | 19,770 | 14,310 | 453 |

| NU-140020-1000 | 1400 x 20 | LUG | 10 | 43 | 12.7 | 10.8 | 21,580 | 15,527 | 798 |

| NU-120024-850 | 1200 x 24 | LUG | 8 | 48.3 | 12.9 | 10.6 | 19,830 | 14,360 | 560 |

| NU-120024-850 | 1200 x 24 | LUG | 8.5 | 48.3 | 12.9 | 10.6 | 20,500 | 14,850 | 585 |

| NU-140024-10000 | 1400 x 24 | LUG | 10 | 52.0 | 12.7 | 10.8 | 26,130 | 20,365 | 721 |

| NU-1400-25-1125 | 1400 x 25 | LUG | 11.25 | 56.9 | 15.3 | 13.2 | 16,860 | 15,170 | 1,322 |

| NU-1405594 | 140/55-9 | LUG | 4 | – | – | – | – | – | – |

| NU-3154512106 | 315/45-12 | LOC | 10 | – | – | – | – | – | – |

| NU-355502010 | 355/50-20 | SMOOTH | 10 | – | – | – | – | – | – |

| NU-400605011 | 400/60-15 | LUG | 11 | – | – | – | – | – | – |

| NU-465552016 | 465/55-20 | SMOOTH & LUG | 16 | – | – | – | – | – | – |

| Available with clip (bead LOC system) | |||||||||

| Other sizes available upon request | |||||||||

Rhino Rubber Scissor Lift Tires & Wheel Assemblies are now available. Please give us a call at 877-744-6603 to complete your order.

Take the pain out of YOUR supply chain.

Join the Rhino Team!

Rhino Rubber, LLC is a global distribution company that provides quality industrial tire products and services. We are looking for dealers and distributors to be a part of the Rhino team that represents “Excellence in Service” with a commitment to the principles of continuous improvement, quality and competitive products. Our team will take the “pain” out of the supply chain process.

Join the Rhino Team. Contact us today at our warehouse: 234-678-7863 or toll free at: 877-744-6603, to become a Rhino dealer or distributor.