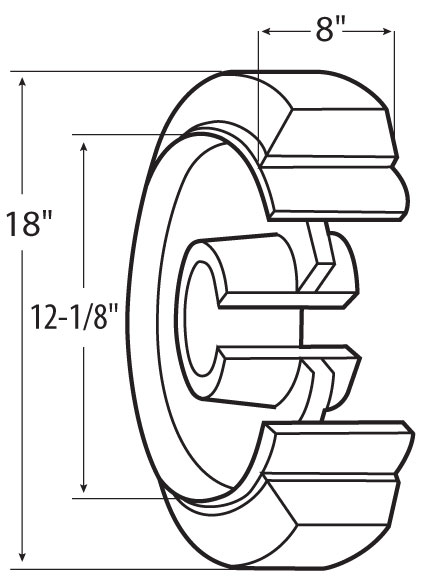

Rubber Press-On Tires

Sometimes called Cushion Tires or Press On Solid Airless Tires, are manufactured utilizing advanced injection molding techniques. This process insures consistent high quality performance, and longer wear when compared against typical compression molded products. Optimized rubber-to-steel adhesion system virtually eliminates bond failures.

Press-on tires are applicable for industrial vehicles running on smooth surfaces.

PRESS-ON Tire Characteristics:

- Low energy consumption

- High chunk and chip resistance

- Lower maintenance cost due to high shock absorption

- High rubber density giving maximum

load carrying - Increased service life

- Good stability and braking properties

- Improved ride quality

CLICK HERE to download a pdf file of the chart.

Cushion Series |

|||||

| Product Number |

Size of Tire (inches) |

Load Capacity | Weight (lbs.) | ||

| 6 Mph | 10 Mph | Smooth | Traction | ||

| RS-955-SM | 9 x 5 x 5 | 1,960 | 1,740 | 13.5 | – |

| SEB-1046.5-SM | 10 x 4 x 6 1/2 | 1,620 | 1,400 | 11.5 | – |

| SEB-1056.5-SM | 10 x 5 x 6 1/2 | 2,070 | 1,840 | 14.8 | – |

| NU-10.556.5-SM | 10 1/2 x 5 x 6 1/2 | 2,200 | 1,940 | 16.0 | – |

| NU-10.556.5-TR | 10 1/2 x 5 x 6 1/2 | 2,200 | 1,940 | – | 15.0 |

| NU-1258-SM | 12 x 5 x 8 | 1,850 | 1,630 | 19.2 | – |

| NU-1258-TR | 12 x 5 x 8 | 1,850 | 1,630 | – | 18.8 |

| SEB-125.58-SM | 12 x 5 1/2 x 8 | 2,740 | 2,430 | 23.3 | – |

| SEB-125.58-TR | 12 x 5 1/2 x 8 | 2,740 | 2,430 | – | 23.3 |

| NU-134.58-TR | 13 x 4 1/2 x 8 | 2,300 | 2,030 | – | 19.0 |

| NU-13.54.58-SM | 13 1/2 x 4 1/2 x 8 | 2,350 | 2,080 | 20.8 | – |

| NU-13.54.58-TR | 13 1/2 x 4 1/2 x 8 | 2,350 | 2,080 | – | 14.5 |

| SEB-13.55.58-SM | 13 1/2 x 5 1/2 x 8 | 3,080 | 2,720 | 25.5 | – |

| SEB-13.55.58-TR | 13 1/2 x 5 1/2 x 8 | 3,080 | 2,720 | – | 25.0 |

| SEB-144.58-SM | 14 x 4 1/2 x 8 | 2,390 | 2,120 | 23.0 | – |

| SEB-144.58-TR | 14 x 4 1/2 x 8 | 2,390 | 2,120 | – | 21.5 |

| SEB-14510-SM | 14 x 5 x 10 | 1,880 | 2,120 | 24.3 | 21.8 |

| SEB-15511.25-SM | 15 x 5 x 11 1/4 | 2,850 | 2,520 | 26.8 | 25.5 |

| SEB-16510.5-SM | 16 x 5 x 10 1/2 | 3,090 | 2,730 | 31.8 | 29.8 |

| SEB-16510.5-TR | 16 x 5 x 10 1/2 | 3,090 | 2,730 | – | 29.8 |

| SEB-16610.5-SM | 16 x 6 x 10 1/2 | 3,920 | 3,460 | 37.8 | – |

| SEB-16610.5-TR | 16 x 6 x 10 1/2 | 3,920 | 3,460 | – | 36.3 |

| SEB-16.25511.25-SM | 16 1/4 x 5 x 11 1/4 | 3,120 | 2,760 | 31.3 | – |

| SEB-16.25511.25-TR | 16 1/4 x 5 x 11 1/4 | 3,120 | 2,760 | – | 29.8 |

| SEB-16.25611.25-SM | 16 1/4 x 6 x 11 1/4 | 3,930 | 3,480 | 36.8 | – |

| SEB-16.25611.25-TR | 16 1/4 x 6 x 11 1/4 | 3,930 | 3,480 | – | 36.0 |

| SEB-16.25711.25-SM | 16 1/4 x 7 x 11 1/4 | 4,740 | 4,190 | 42.0 | 41.0 |

| NU-17512.18-SM | 17 x 5 x 12 1/8 | 3,230 | 2,850 | 32.0 | – |

| NU-18512.18-SM | 18 x 5 x 12 1/8 | 3,360 | 2,980 | 35.8 | – |

| NU-18512.18-TR | 18 x 5 x 12 1/8 | 3,360 | 2,980 | – | 35.5 |

| SEB-18612.18-SM | 18 x 6 x 12 1/8 | 4,290 | 3,800 | 44.0 | – |

| SEB-18612.18-TR | 18 x 6 x 12 1/8 | 4,290 | 3,800 | – | 42.8 |

| SEB-18712.18-SM | 18 x 7 x 12 1/8 | 5,220 | 4,620 | 52.8 | – |

| SEB-18712.18-TR | 18 x 7 x 12 1/8 | 5,220 | 4,620 | – | 50.3 |

| SEB-18812.18-SM | 18 x 8 x 12 1/8 | 6,150 | 5,440 | 61.0 | – |

| SEB-18812.18-TR | 18 x 8 x 12 1/8 | 6,150 | 5,440 | – | 58.5 |

| NU-18912.18-SM | 18 x 9 x 12 1/8 | 7,080 | 6,270 | 68.3 | – |

| NU-18912.18-TR | 18 x 9 x 12 1/8 | 7,080 | 6,270 | – | 63.0 |

| NU-20816-SM | 20 x 8 x 16 | 6,930 | 6,130 | 62.0 | – |

| NU-20816-TR | 20 x 8 x 16 | 6,930 | 6,130 | – | 58.8 |

| NU-20916-SM | 20 x 9 x 16 | 7,960 | 7,060 | 90 | – |

| NU-20916-TR | 20 x 9 x 16 | 7,980 | 7,060 | – | 90 |

| NU-21615-SM | 21 x 6 x 15 | 4,820 | 4,270 | 52 | – |

| SEB-21615-TR | 21 x 6 x 15 | 4,820 | 4,270 | – | 52 |

| SEB-21715-SM | 21 x 7 x 15 | 5,870 | 5,200 | 66.3 | – |

| SEB-21715-TR | 21 x 7 x 15 | 5,870 | 5,200 | – | 62.3 |

| SEB-21815-SM | 21 x 8 x 15 | 6,930 | 6,130 | 76.0 | – |

| SEB-21815-TR | 21 x 8 x 15 | 6,930 | 6,130 | – | 71.3 |

| SEB-21915-SM | 21 x 9 x 15 | 7,980 | 7,060 | 86.0 | – |

| SEB-22816-SM | 22 x 8 x 16 | 7,170 | 6,340 | 75.0 | – |

| SEB-22816-TR | 22 x 8 x 16 | 7,170 | 6,340 | – | 71.8 |

| SEB-22916-SM | 22 x 9 x 16 | 8,260 | 7,310 | 89.0 | – |

| SEB-22916-TR | 22 x 9 x 16 | 8,260 | 7,310 | – | 79.8 |

| SEB-221016-SM | 22 x 10 x 16 | 9,350 | 8,270 | 103 | – |

| SEB-221016-TR | 22 x 10 x 16 | 9,350 | 8,270 | – | 103 |

| SEB-221216-SM | 22 x 12 x 16 | 11,530 | 10,200 | 124.0 | – |

| SEB-221216-TR | 22 x 12 x 16 | 11,530 | 10,200 | – | 115.0 |

| NU-221416-SM | 22 x 14 x 16 | 13,710 | 12,130 | 167.2 | – |

| NU-221616-SM | 22 x 16 x 16 | 15,890 | 14,060 | 173.8 | – |

| NU-281022-SM | 28 x 10 x 22 | 11,200 | 9,910 | 153.5 | – |

| SEB-281222-SM | 28 x 12 x 22 | 13,820 | 12,220 | 182.8 | – |

| SEB-281222-TR | 28 x 12 x 22 | 13,820 | 12,220 | – | 168.5 |

| NU-281622-SM | 28 x 16 x 22 | 19,040 | 16,840 | 242.2 | – |

| NU-361030-SM | 36 x 10 x 30 | – | – | – | – |

| NU-362030-SM | 36 x 20 x 30 | – | – | – | – |

| NU-401430-SM | 40 x 14 x 30 | – | – | – | – |

| NU-401630-SM | 40 x 16 x 30 | 27,770 | 24,560 | 425 | – |

| NU-402030-SM | 40 x 20 x 30 | – | – | – | – |

| Available compounds: • Universal • Non-marking |

|||||

| Other sizes available upon request | |||||

Take the pain out of YOUR supply chain.

Join the Rhino Team!

Rhino Rubber, LLC is a global distribution company that provides quality industrial tire products and services. We are looking for dealers and distributors to be a part of the Rhino team that represents “Excellence in Service” with a commitment to the principles of continuous improvement, quality and competitive products. Our team will take the “pain” out of the supply chain process.

Join the Rhino Team. Contact us today at our warehouse: 234-678-7863 or toll free at: 877-744-6603, to become a Rhino dealer or distributor.